Annealed Receiver

A style of receiver logo used on the earliest International Harvester rifles, in which the arrangement of the text lines resembles an arrowhead. Collectors believe these were supplied by Springfield Armory and are among the very first rifles produced by IHC.

A style of receiver logo used on the earliest International Harvester rifles, in which the arrangement of the text lines resembles an arrowhead. Collectors believe these were supplied by Springfield Armory and are among the very first rifles produced by IHC.

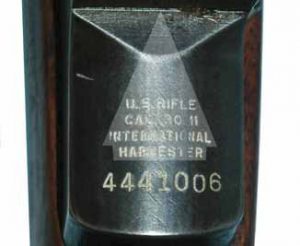

Arrowhead

A style of receiver logo used on the earliest International Harvester rifles, in which the arrangement of the text lines resembles an arrowhead. Collectors believe these were supplied by Springfield Armory and are among the very first rifles produced by IHC.

Base

Properly “bracket”; the dovetail base fastened to the receiver of the M1C Sniper rifle. The telescope and mount slide onto the bracket. See M1C.

Birch

The wood used to make replacement stocks and handguards in the late 1950′s. Original specifications called for walnut, but difficulty in obtaining it resulted in a switch to birch in some rebuild programs and for replacement guards.

Bright Chamber

In original assembly at Springfield Armory, the chamber area of the barrel was not Parkerized and appears bright. During rebuild, a newly refurbished barrel/receiver assembly was refinished and the chamber area Parkerized in the process. A bright chamber is a clue to originality.

British Proofs

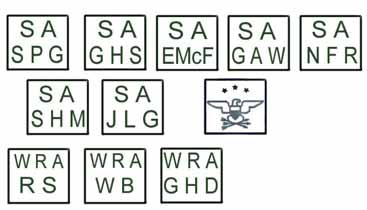

Cartouche

The collector term for the mark stamped into the left side of the stock upon original acceptance of the rifle by the government. The earliest stamps bore the initials of the manufacturer over the initials of the inspector under whose authority it was accepted. In late 1940 the Springfield Armory format was changed to use the initials of the armory Commandant. At Winchester the new type used GHD, the initials of the Chief of Ordnance. In 1953 the old cartouche was changed to the boxed Eagle and Stars called the Defense Acceptance Stamp. Springfield, Harrington & Richardson, and International Harvester all used the DAS from that time onward.

CMP

Civilian Marksmanship Program headquartered in Anniston, Alabama, formed in 1996 to succeed the DCM. All M1 rifles in Army inventory were transferred to them for sale to qualified buyers. CMP supports the National Matches at Camp Perry. See thecmp.org.

Camp Spring

Properly “compensating spring.” A small spring butted to the front of the keystone operating rod spring to improve functioning in early rifles. This required a follower rod with a thin body over which the comp spring fit. The comp spring was eliminated in 1940 (see KEYSTONE SPRING).

Curved Side

The profile of the operating rod boss. Early rod bosses were cut in an arc; later rods were cut straight.

Danish

Rifles loaned to Denmark during the Cold War and returned by them in 1998. CMP sold these rifles to the public.

Dash

A component of some parts marking (see DRAWING NUMBER). Some parts marking included a dash between the letter of the mark and the main number, as well as a dash between the number and the Revision Number. Parts marks with dashes are usually earlier than the same number without a dash.

Dash Number

The revision number, often separated from the main part number by a dash. The part blueprint was revised when some element of construction was changed, even if the change did not entail a change of shape. Parts constructed according to the new drawing were marked with the number of the revision to the original drawing. The digit 4 in B-8881-4 above represents the fourth revision to the original long butt plate screw

DCM

Department of Civilian Marksmanship, a government agency created in 1916 to encourage shooting by civilians as a cadre in time of war. DCM sold surplus military weapons and ammunition to qualified civilians as part of the mission. Political controversy surrounded this program, and it was privatized as the Civilian Marksmanship Program in 1996, ending government involvement in weapons sales. All M1 rifles in Army inventory were transferred to the newly formed CMP.

Demil

A government process used to “demilitarize” or destroy rifles by cutting the receiver and barrel in half. Hundreds of thousands of rifles were demilled and the receiver halves sold as scrap (see REWELD). Modern demilling uses a shredder nicknamed “Captain Crunch”.

Drawing Number

A number stamped into many parts, indicating the blueprint covering the construction of that part. This number was also the Part Number, and was composed of a letter indicating the size of the blueprint, a unique number assigned to that part, and a number indicating the revision to the original drawing. In early rifles most parts were numbered, but most parts marking was dropped under the pressure for increased production.

Extra Hole

A hole bored into early triggers; dropped in 1941.

Field Strip

To disassemble a rifle into the three main groups: barrel and receiver, stock, and trigger group.

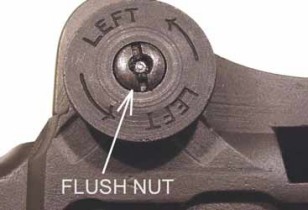

Flush Nut

The small nut that held the rear sight elevation knob in place on early rifles. Because the sight tended to loosen, the flush nut was replaced by a rectangular bar that could apply greater tension (see LOCK BAR).

Gap Letter

A style of receiver logo on International Harvester rifles, in which there is a space between U.S. and RIFLE and between CAL. and .30M1. These receivers were supplied by Springfield Armory to help IHC meet production quotas.

Gas Port

The hole in the barrel admits propellant gas into the gas cylinder. The GCA standardized the term “Gas Port Rifle” to identify the spline-type gas system used from 1940 to replace the original Gas Trap system.

Gas Trap

The collector term was standardized by the GCA in 1995 for the first type of gas system that utilized a false muzzle to deflect or “trap” the gas into the gas cylinder. The early barrel was threaded at the muzzle and the gas cylinder screwed onto it. The gas plug slipped into the front of the cylinder and was held in place by a screw. This system caused accuracy problems because the plug through which the bullet passed deformed under the heat generated by rapid-fire. It was replaced in late 1940 by the “Gas Port” system in which the gas entered the cylinder through a hole bored in the barrel. The gas cylinder slipped onto three splines cut into the barrel and the gas plug was eliminated. Approximately the first 50,000 rifles used the Gas Trap system, but almost all of them were eventually upgraded to the Gas Port design. Unmodified rifles and parts command a huge premium from collectors.

Greek

Any of the M1’s loaned to Greece during the Cold War and returned to the CMP in 2002 for sale to the public.

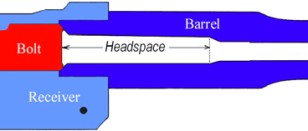

Headspace

The length of the bullet chamber as measured from the face of the closed bolt to a datum point in the barrel where it contacts the cartridge. The GI acceptable .30-06 measurement can vary from 1.940 inches to 1.949 before rejection. A rifle with excessive headspace is dangerous to fire.

Heat Lot

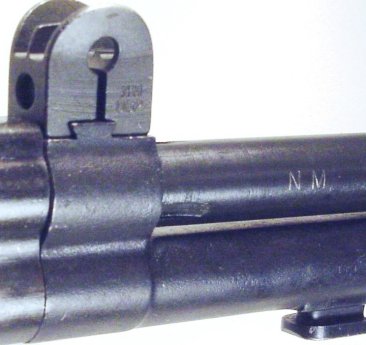

A code stamped into the receiver, bolt, and barrel to identify the batch of steel used. Raw material delivered by the steel supplier included a list of the alloys in the batch. Springfield metallurgists assigned a code to that batch or “heat” (also “melt”) of steel. The code identified the supplier and the lot, such as REP 23A. The heat lot was a quality control measure that would allow all parts made from a particular batch to be identified if problems like cracking developed.

Keystone Spring

The operating rod spring used on early models is made from keystone-shaped wire that appears square. The operation of this spring was sometimes sluggish, and a second “compensating” spring was added. In 1940 the Wallace Barnes Company developed a roundwire spring that replaced both and was used from 1941 to the end of production.

Late

Any part with final characteristics that is familiar to all.

Lend Lease

During the early days of WW II the US sent large quantities of weapons to Great Britain, including 38,001 M1 rifles. Most of these rifles were not used and were imported back to the US by Interarmco for sale on the civilian market. They bear a series of British proof marks, usually in the barrel date area. When imported, these rifles also carried a band of red paint around the front handguard denoting that they are not the standard British caliber, but this mark was usually removed by collectors. See BRITISH PROOFS.

LMR

The contractor code for Line Material Company, a producer of barrels in the Korean War era. LMR supplied barrels for International Harvester rifles. Some were used by Harrington & Richardson and for rebuild programs. They were especially accurate, and a small number were used by Springfield Armory on National Match rifles.

Lock Bar

A rectangular part is used to tighten the rear sight. Early sights often loosened during firing, and the retaining nut was replaced by a bar that could apply greater tension (see FLUSH NUT). After WW II a satisfactory sight without lock bar was used.

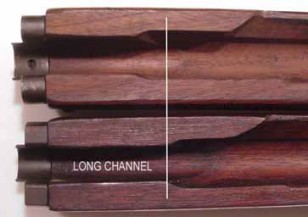

Long Channel

The front portion of the barrel channel in early stocks. The length of this channel was reduced after the occasional binding of the operating rod was encountered.

M1C

The standard M1 Sniper rifle of late WW II using the Griffin and Howe scope mounting system. This system consisted of a dovetail bracket or “base” screwed to the receiver and a ring mount that slid onto it. The telescope used was the military version of the Lyman Alaskan designated either M81 or M82 according to the reticule. Although there is no evidence of its use in WW II, it was employed in the Korean War.

M1D

The John Garand design of the M1 Sniper rifle employs a mounting block on the barrel. Although initially rejected in favor of the M1C, it soon replaced the C as the standard and lasted into the Viet Nam era. The telescope most commonly used on the D was the M84.

MC-1

USMC nomenclature for the telescope and mount used on their improved M1C Sniper rifles. Collectors sometimes incorrectly refer to the rifle as MC-1. This version is properly called the M1952 and features a Kollmorgen telescope and a larger mount.

Milled

A part machined from a solid piece of metal. Most parts were made by a complicated series of machine cuts until the pressure of WW II led Springfield to find ways to make them cheaper and faster. Many previously milled parts were then made by bending or stamping metal into shape.

Mix Master

A rifle with a mix of parts not original to first assembly. Parts scrambling usually resulted from a rebuild program in which any serviceable component was used to reassemble the refurbished rifle. A Winchester part on a Springfield rifle is an example.

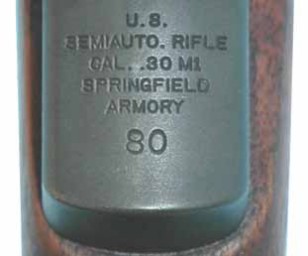

Model Shop

A research and development facility at Springfield Armory. The first 80 M1 rifles were constructed under the personal supervision of John Garand. Collectors call those rifles the Model Shop Rifles. Mass production began with #81.

Muzzle Wear

The condition of the front of the bore. Excessive wear at the muzzle can affect accuracy. Most collectors value low MW.

National Match

The target version of the M1 rifle was developed by Springfield Armory for the National Matches held annually at Camp Perry and for general competition shooting. Springfield produced these rifles from 1953 through 1963. DCM sold NM rifles to qualified buyers from 1955 to 1973.

No Trap

An early buttstock without provision for storage of cleaning equipment in the butt. Both Springfield and Winchester initially made rifles with a solid, one-piece butt plate covering the rear of the stock. Although the stock had lightning holes, there was no access to them. In 1940 a new butt plate with a small trap door was instituted, and the rear of the stock was inletted to accommodate the hinge. Original no-trap stocks are highly prized by collectors restoring older rifles to original condition.

Numbered

A part marked with its drawing number. Practically all parts on early rifles were numbered. The earliest marks used the drawing size letter followed a dash and the part number. As mass-production increased, the dash between the letter and number was usually dropped in favor of just a space, and later the space was omitted. Finally, the parts mark was dropped altogether. There are exceptions to the normal sequence. See DRAWING NUMBER, DASH.

Ordinance Wheel

The Ordnance Department escutcheon consists of crossed cannons in a circular border. This stamp was superseded by the Defense Acceptance Stamp in 1953.

Postage Stamp

A style of receiver logo on International Harvester rifles in which all lines of text are of equal length. This style is the standard marking for the bulk of IHC production.

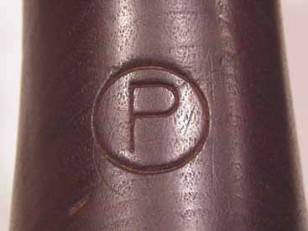

Proof P or Circle P

A mark in the pistol grip of the stock indicates high-pressure testing. All rifles were so marked as part of initial acceptance tests, and the lack of the mark indicates either extensive wear, sanding, or replacement stock. Various styles of P.

Rebuild

The process of refurbishing worn rifles. Rebuilding began early in M1 history as rifles became worn during use. In the process the rifle was completely disassembled, worn barrels replaced, and the rifle was usually refinished. Any serviceable parts were used in reassembly, resulting in a mix of early or late parts of all manufacturers (see MIXMASTER). An early marking of rebuilt rifles was SA-52 stamped behind the rear sight. Later rebuild programs employed electric pencil markings on the right front receiver leg to indicate the rebuild facility and the date of the rebuild.

Red Band or Red Point

A British marking to show that a weapon was not the standard British caliber. In rifles, the regulation called for a band of red paint near the lower band and the caliber written in black as .30 or .300; see LEND LEASE.

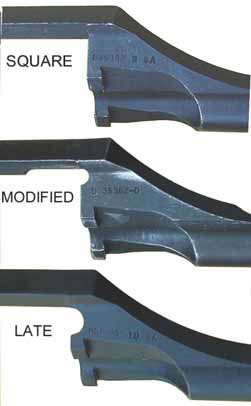

Relieved (Stress)

The small cut is made in the corner of the operating rod where the saddle joins the shank. Early rods were cut square at that point and were subject to cracking in the corner. Many older rods were modified with a stress-relief cut, and later rods were manufactured with the cut.

Repro

A reproduction part; not original GI. Often a fake is represented as original.

Restoration

The process of returning a rifle to its original configuration. Many collectors want rifles in “as manufactured” condition and will replace incorrect parts with the versions that were used at the time the rifle was originally made (see MIXMASTER).

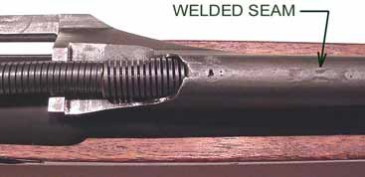

Reweld

is The common collector term for a rifle made from demilled receiver halves (see DEMIL). In the 1960’s and 1970’s the government destroyed surplus M1 rifles by cutting the receiver in half with a torch. Dealers bought the scrap halves and welded them back together to make rifles, especially the so-called “Tanker” Garands.

Sight Seal

A sheet metal cover pressed over the front sight screw to prevent tampering with the factory setting. The seal was eliminated in 1943 and was removed from earlier rifles during the rebuild. An intact seal is prized by collectors of original rifles. Reproduction seals exist.

Single Slot

The early gas cylinder lock screw without poppet valve. Also called “solid screw.” Replaced by valve-type in 1943.

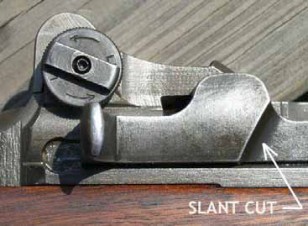

Slant Cut

The shape of the front of the operating rod boss. Early Springfield rods and most Winchester rods were cut at an angle in front. Later SA and all Korean era producers used a later version with a vertical front cut.

Square Spring

The operating rod spring used on early models, is made from keystone – shaped wire that appears square. The operation of this spring was sometimes sluggish, and a second “compensating” spring was added. In 1940 the Wallace Barnes Company developed a roundwire spring that replaced both and was used from 1941 to the end of production. See Keystone Spring.

Stamped

A part made by stamping or bending it to shape, rather than by a series of machine cuts (see MILLED)

Tanker

A deceptive term for a shortened commercial version of the M1. Near the end of WW II a cut down M1 was tested and rejected. Gun dealers later began to manufacture this type to sell many of the welded receivers they had made (see Reweld), and coined the term “Tanker” to suggest use by tank crews.

Throat Erosion

The amount of wear to the rear of the bore. Erosion is measured with a Throat Erosion Gage, and a reading of 5 or more indicates wear that could affect accuracy. Collectors consider TE in their valuation of a rifle.

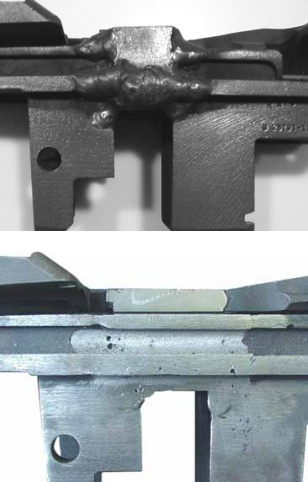

Two Tone

Also Lead Pot Annealed. A process used to soften the rear of the receiver to prevent cracking when struck by the bolt during recoil. After the development of the grenade launcher, a new steel alloy less prone to cracking was used to make receivers. Older receivers were dipped in molten lead to reduce brittleness. This process darkened the appearance of the dipped section, resulting in “two-tone” receivers.

Type 1 National Match

The early version of the target rifle made by Springfield Armory from 1953 to 1959. These rifles were essentially standard rifles built to exact specifications and selected for accuracy. Collectors pay a premium for this type versus the second type called Type 2.

Type 2 National Match

The later version of the National Match rifle. Springfield Armory instituted annual accuracy improvements that in 1960 included fiberglass bedding to mate the stock to the receiver and trigger group. Collectors considered these bedded rifles as different from the earlier Type 1 and identified them as Type 2. They were manufactured from 1960 to 1963 and were the ultimate version of the target rifle.

Welded Seam

The first type operating rod used on Model Shop rifles and approximately the first 2000 production guns. This rod was a one piece assembly in which the handle and the tube were machined from a single piece of stock. The tube section was folded around a mandrel and welded along its entire length. An extremely rare early part.

WIN 13

Late Winchester receivers serial numbered in the 1,600,000 range and with drawing number D28290WIN-13. The story of these receivers is not fully understood, as Winchester had reached the upper 2,500,000 serial range prior to producing these in a serial range assigned to and used by Springfield Armory two years earlier.